- Systems

Membranes

Metal Roof and Wall Systems

Coatings and Retrofit

- Components

- Technical Documents

- Resources

- Applications

- About

- Contact

Experience long-term durability while reducing time and labor

Whether using custom-fabricated deck sheets or any of the roll goods in our extensive portfolio, Duro‑Last also offers custom-fabricated accessories which reduces rooftop labor on the most critical roof areas — penetrations and transitions. Many of these accessories, including metal scuppers, collector boxes and flashings for difficult areas like corners and parapet wall transitions, come with pre-welded membrane skirts. It all adds up to faster, quieter and easier installation with less maintenance and reliable roof performance for years to come.

Completing up to 85% of the welding in our factory-controlled environment provides an aesthetically pleasing finished product along with the necessary watertight integrity.

Rooftop labor is greatly reduced, getting your roofing crews off the roof faster and on to the next job.

Most leaks in single-ply roofing systems are caused by imperfect seams and poor workmanship. The more seams done on the jobsite, the greater the potential for leaks down the road.

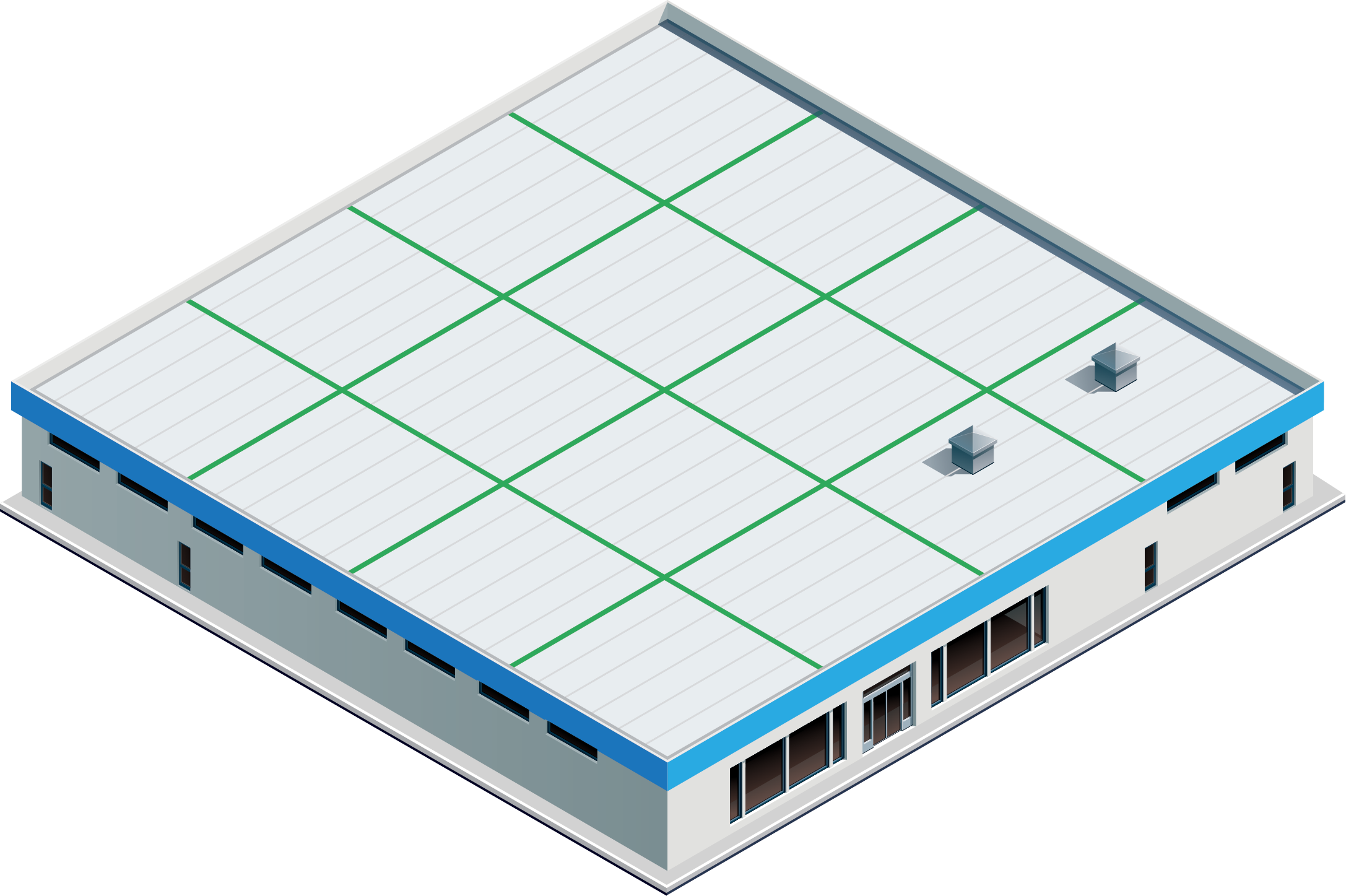

A typical 50,000-square-foot roof pieced together from traditional rolled roofing membrane requires more than 7,500 linear feet of rooftop seaming. By comparison, less than 1,300 linear feet of seaming is required with the custom-fabricated Duro‑Last Roofing System. Reduce your risk with Duro-Last custom-fabrication.

Calculated using 5’ laps. Lighter lines represent factory seams.

Green lines represent field seams.

Calculated using 6’ wide roll good systems.

Blue line represent field seams.

Roofing Systems

Components