- Systems

Membranes

Metal Roof and Wall Systems

Coatings and Retrofit

- Components

- Technical Documents

- Resources

- Applications

- About

- Contact

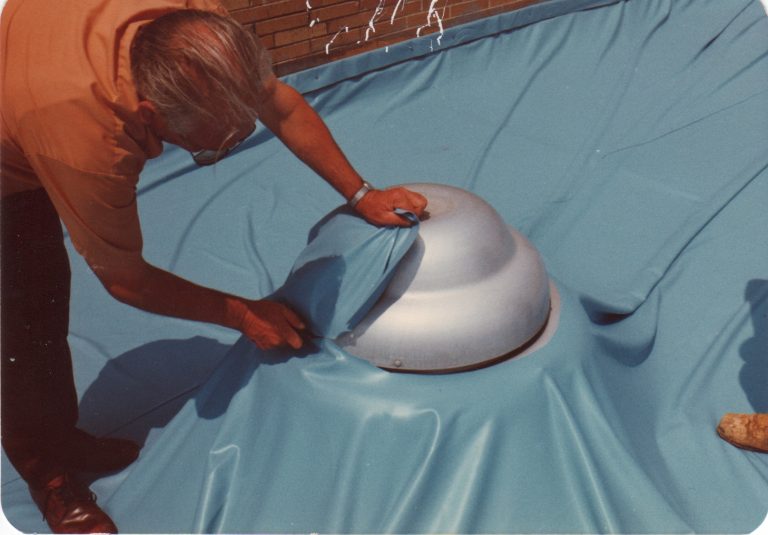

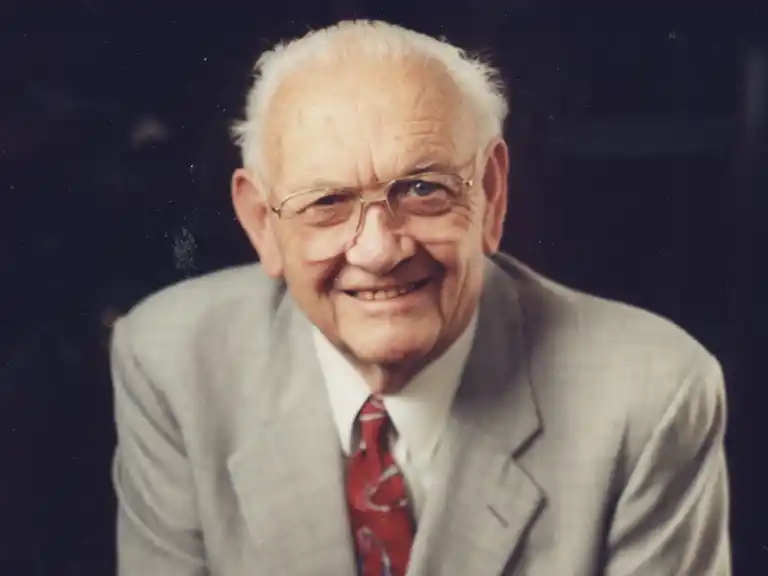

The Duro‑Last story begins with founder, John R Burt, whose life was defined by perseverance, hard work and an entrepreneurial spirit. After working as a lumberjack, carpenter, tool and die maker and soldier, among other jobs, John got into the swimming pool business. When a liner he had purchased failed, he recognized the importance of vertical integration to control quality and founded Tri-City Vinyl to manufacture his own pool liners. One day it occurred to him: If his product could keep water in, it could keep water out. In 1978, that insight led to development of the Duro‑Last Roofing System.

Founder, John R Burt, was 58 years old when he started a small business that has grown to be the world’s largest manufacturer of custom-fabricated roofing systems. John’s unique skill set and entrepreneurial spirit eventually led to success, but not without overcoming multiple hurdles along the way.

Read the remarkable story of John and Mildred’s vision and perseverance as they built the world’s best roof.

In 1963, John joined with friends to form Bridgeport Pools. Although successful, John began experiencing problems with faulty pool liners, which led him to realize that to control the quality, he had to make them himself. In 1977 he did just that, and Tri-City Vinyl was born. This was the beginning of the enterprise that would last more than four decades and be the catalyst for the creation of the “Worlds Best Roof®”.

1963 John joins friends Earl Leidlein and Carl DeMaet to form Bridgeport Pools.

1969 John becomes sole owner of Bridgeport Pools.

1975 John’s son, Jack Burt, and daughter, Sharon Sny, started working for Tri-City Vinyl.

1975 Bridgeport Pools reaches $2 million in sales.

1975 Tri‑City Vinyl begins manufacturing its own pool liners.

1977 Tri City Vinyl was incorporated.

1978 John’s daughter, Kathy Burt Allen, joined the business and started working for Tri-City Vinyl on March 1.

1978 First Duro‑Last roof is installed.

1981 Duro‑Last was incorporated.

1981 Duro-Last had seven employees and finished the year with $200,000 in sales.

1982 John purchased a 75,000-sq.-ft. facility at 525 Morley Drive in Saginaw, Michigan, on April 30. 18,000 sq. ft. was set aside for office space and 57,000 sq. ft. for manufacturing.

1982 Duro-Last grew to 17 employees and reached $2 million in sales.

1983 On February 28, John’s son-in-law, Bob Moeller, became the first Duro-Last Independent Sales Representative.

1983 From its humble beginnings to a well-respected business, Duro-Last held its first National Sales Seminar in Saginaw, Michigan, in 1983. Over 100 people attended the first seminar, which was a huge success full of new ideas and inspiring training sessions.

1984 Duro-Last became a registered trademark in the United States.

1984 John began a vertical integration strategy with the purchase of an additional facility at 725 Morley Drive in Saginaw, Michigan, adding 57,000-sq.-ft. of warehouse space and 1,600 sq. ft. for producing roofing accessories.

1985 Duro‑Last expands to Grants Pass, Oregon.

1985 On September 2, Tom Lawler became John’s business partner at Duro-Last as well as the company’s General Counsel.

1985 Duro-Last grew to 77 employees and reached $12 million in sales.

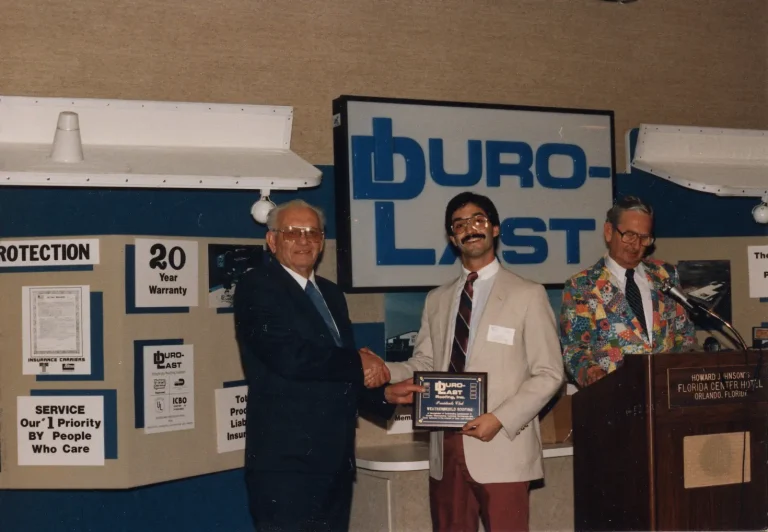

1986 Just three years after its first National Sales Seminar, Duro-Last tripled the number of attendees in 1986 at the first seminar held outside Michigan. Meeting in Orlando, Florida, at the Howard Johnson’s Conference Center, 300 attendees enhanced their knowledge in sales, installation, bidding and problem solving while having fun in the sun.

1986 John was presented with the Governor’s New Product Award.

1986 John continued his vertical integration strategy. He purchased an extruder to manufacture roofing drip edge, gravel stop, and termination bars and installed two injection molders to produce roofing plates.

1987 John was awarded the Small Businessperson of the Year Award by then Governor James Blanchard.

1988 Vertical integration continued with the purchase of Duro-Last’s first laminator.

1988 Duro-Last grew to 175 employees and reached $25 million in sales.

1989 John begins recycling operations with the production of a proprietary rooftop walkpad, ROOF‑TRAK®.

1990 Oscoda Plastics®, Inc. made the front page of The Saginaw News’ Business & Labor section when its recycled flooring, made from Duro-Last roofing scrap, hit the Big Screen in Space Cowboys and Armageddon. In both films, scenes were shot at NASA’s Astronaut Buoyancy Training Tank, where over 50,000-sq.-ft. of Oscoda flooring was installed. By 2000, Oscoda flooring was making its mark in the industry, appearing in national restaurant and shopping chains, NHL ice rinks and even at Disneyland® Resort.

1991 John received the Saginaw County Chamber of Commerce’s competitive business honor, the Brick Award, in 1991. John was recognized for Duro-Last’s large contribution to Saginaw’s economy through job development, site enhancements and growth as well as technological advancements.

1991 John was awarded the Michigan Entrepreneur of the Year Award in the Construction category, as well as the Inventor/Entrepreneur Award.

1992 John and Mildred celebrated their 50th wedding anniversary.

1993 S & S Plastics moves to Oscoda, Michigan, and officially changes its name to Oscoda Plastics®, Inc.

1994 Duro‑Last opens a fully operational 80,000-sq.-ft. manufacturing plant in Jackson, Mississippi.

1995 “World’s Best Roof®” becomes a registered trademark.

1995 Duro-Last grew to 350 employees and reached $52 million in sales.

1996 Plastatech completed construction on a 72,000-sq.-ft. manufacturing facility in Saginaw, Michigan. The facility included a state-of-the-art calender to manufacture the film component of the Duro-Last membrane.

1996 Duro‑Last opens 60,000-sq.-ft. manufacturing facilities in Sigourney, Iowa, and Grants Pass, Oregon.

1997 On April 28, John’s grandson Shawn Sny started working at Duro-Last full-time.

1998 John was presented the Vison of Free Enterprise Award.

1999 TIP‑TOP® Screw Manufacturing, Inc. opens in Oscoda, Michigan.

2001 The Duro-Last National Sales Seminar was held at Disney’s Colorado Springs Resort in Orlando, Florida. Over 1,000 Duro-Last contractors, sales representatives and their families attended.

2001 John R Burt Enterprises exceeded $100 million in sales.

2003 Duro-Last celebrated its 25th anniversary of manufacturing the Duro‑Last Roofing System.

2003 Duro‑Last introduces EXCEPTIONAL® Metals.

2003 On April 11, 2003, at the age of 82, John passed away.

2003 John was posthumously presented the Davenport University Excellence in Business Award, which was accepted by Mildred.

2004 John’s grandson, Jason Tunney, began working for Duro‑Last on September 30.

2004 Vice President Dick Cheney visited Duro‑Last’s corporate headquarters and Plastatech in Saginaw, Michigan, to recognize the companies’ consistently strong sales and employment growth.

2004 Duro-Last reached 1 billion sq. ft. of manufactured membrane.

2005 Duro-Last expanded its corporate headquarters. The high-tech, two-story expansion included approximately 18,000-sq.-ft. of office space with renovations to the existing structure’s façade and offices.

2006 John R Burt Enterprises exceeded $150 million in sales.

2008 Duro-Last celebrated its 30th year of supplying top-quality roofing systems throughout North America.

2009 John’s grandsons, Shawn Sny and Jason Tunney, were elected to the Board of Directors.

2010 On January 1, Dan Murphy Jr. was elected to the Board of Directors.

2011 On March 31, Tom Saeli joined John R Burt Enterprises as the first non-family member Chief Executive Officer.

2012 Duro‑Last introduces Duro‑Tuff® roll goods and Duro‑Guard® insulation to its product line.

2013 The Duro-Last National Sales Seminar was held at the Hyatt Manchester Grand in San Diego, closing with a party aboard the aircraft carrier USS Midway.

2013 Duro‑Last and EXCEPTIONAL Metals plant opens a 89,000-sq.-ft. facility in Carrollton, Texas.

2013 Duro-Last reached 2 billion sq. ft. of manufactured membrane.

2013 John R Burt Enterprises grew to 665 people and reached $200 million in sales.

2014 New Duro‑Last EV, Duro‑Tuff and Duro‑Fleece colors were introduced.

2014 Plastatech completed the installation of a new extruder, the largest and most advanced of its kind, in the Saginaw, Michigan, manufacturing facility.

2015 Duro‑Last releases the first product-specific Environmental Product Declaration for single-ply PVC roofing membranes.

2015 The Duro‑Last flagship PVC membrane achieves certified gold status by NSF/ANSI 347.

2016 Duro‑Tuff, Duro‑Fleece and Duro‑Last EV membranes earn certified gold status by NSF/ANSI 347.

2016 Duro‑Last acquires ANViL Paints & Coatings, based in Largo, Florida.

2017 The Duro-Last membrane achieved platinum status.

2017 Duro‑Last opens a 60,000-sq.-ft. facility in Ludlow, Massachusetts.

2018 Duro-Last celebrated its 40th anniversary.

2020 In response to the urgent needs of front-line workers during the COVID-19 pandemic, Duro-Last shifted production to manufacture a variety of PPE equipment including hand sanitizer, face coverings, sanitization wipes, and isolation gowns. Safe Stuff PPE was born.

2021 Duro-Last expanded its line of custom roofing solutions, introducing the Duro-Last X™ (DLX™) membrane. Manufactured solely on the extruder, DLX is a 10-foot-wide roll good featuring Duro-Last’s proprietary membrane formulation that offers the industry’s first option for custom-cut lengths.

2022 TIP-TOP Screw enhances its manufacturing capabilities with the addition of the AMBA bolt maker. This comprehensive machine produces #14 and #15 screws from 5″ to 24″ in length utilizing an integrated approach which incorporates bolt heading, pointing and thread rolling into a single process.

2022 Duro‑Last partners with DuPont to introduce Duro‑Life™ 600.

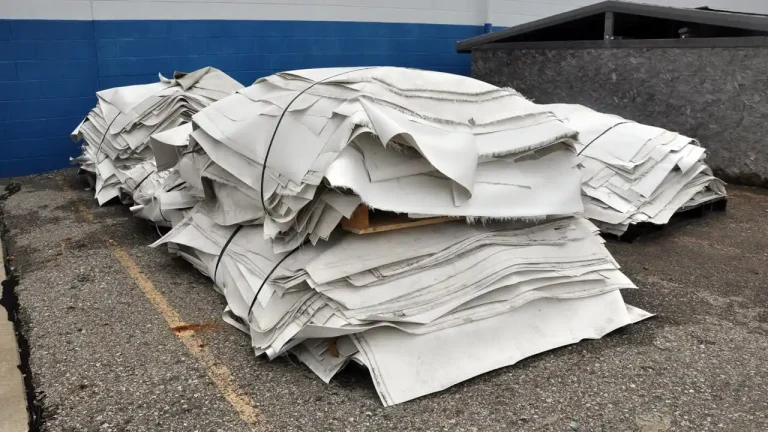

2022 Duro-Last strengthens its commitment to sustainability with the expansion of recycling capabilities. Upgraded machines shred and grind recycled membranes while also separating scrim from the processed material. An extruder and pelletizer then turn the processed material into pellets to be recycled into a variety of products including new roofing membranes, rooftop walkway pads, commercial flooring and concrete expansion joints.

2023 Duro-Last opens its seventh manufacturing facility in Largo, Florida. The 16,000-sq.-ft. building manufactures Duro-Last custom-fabricated membranes and accessories. The Largo facility is also home to Duro-Last’s paints, coatings and caulk manufacturing operations.

2023 Holcim Building Envelope completes the acquisition of Duro‑Last.

2025 Duro‑Last introduces Duro‑TECH™ TPO line of membranes, accessories and adhesives.

2025 Duro-Last opens its eighth manufacturing facility in Kernersville, North Carolina. The 104,000-sq.-ft. state-of-the-art facility manufactures custom-fabricated membranes and accessories as well as metal edge and drainage components.

2025 A new era begins. Following a successful spinoff from Holcim, Amrize launches as an independent, U.S.-based company publicly listed on the New York Stock Exchange. Duro-Last is a core brand within the Amrize Building Envelope division.

2025 Duro-Last relocates its Texas manufacturing operations to a new 130,000-sq.-ft. facility in Dallas. The upgraded site expands operational capacity by more than 40% and features a streamlined layout designed to improve production efficiency, boost inventory capabilities and strengthen support for contractors throughout the Southern U.S.

Roofing Systems

Components